EPCM (Engineering, Procurement, Construction, Management)

Main Objectives:

- services in evaluating options of technologies including audit and feasibility study and expediency;

- identification of target customers and supplier;

- comparative analysis of competiveness;

- evaluation of power efficiency;

- basic and technical design, development of the feasibility projects, work related documentation, production design work, crane production design work, expert opinions;

- performing duties and functions of the General Contractor;

- production and delivery services;

- installation and construction work performance;

- balancing and commissioning;

- registration of documentation on object.

MAJOR COMPLETED PROJECTS

2014 – 2016 Construction of electric boiler station No.1 (North) of the Boguchansky Aluminium Factory in the Boguchany region, Krasnoyarsk Territory

Client: ZAO“Boguchansky Aluminium Factory”

Period of execution: August 2013 – December 2014; April 2015 – present time

Scope of work:

- Development of Work Performance Project, preparatory work;

- Earth work with excavation of foundation pits.

- The equipment and building foundation works.

- Installation of the prefabricated reinforced concrete structures.

- Manufacturing and installation of the construction metal structures.

- Setting up the building envelope and the roofing.

|

|

|

|

|

|

|

|

|

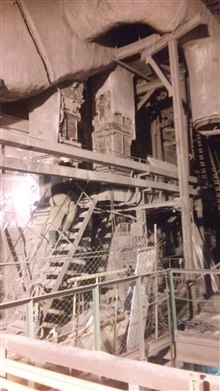

2016 Running repairs of the process equipment, piping systems, structures and transfer mechanisms

Client: OAO Ilim Group Ust-Ilimsk office

Period of execution: July 2016

Scope of work:

- Repair of the I.D.fan of Soda Recovery Boiler SRB-2

- Replacement of the hot water pipeline at the line of pumps

|

|

|

||

|

|

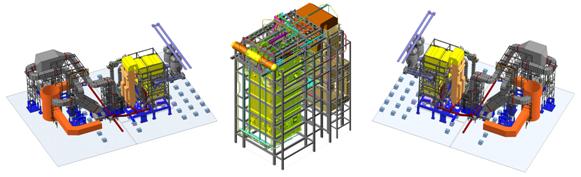

2015 – 2016 Modernization of a boiler unit E-75-40K, station No. 16

Client: OAO Ilim Group Ust-Ilimsk office

Period of execution: 2015 – 2016

Scope of work:

Modernization of a boiler unit E-75-40K, station No. 16, with the performance increased up to 75 tph (without combustion of the backup fuel) using the fluidized bed combustion technology:

- Dismantling of the boiler unit of E-75-40K.

- Preparatory works:

- Taking the utility networks out of the constructions footprint;

- Works on the rooftop (the dismantling of the coverage items and roof slabs, reinforcing of the support pillars, installation of the temporary roof slabs, the roof maintenance, waterproofing application).

- Acting as the General Designer.

- Acting as the General Supplier.

- Acting as the General Contractor.

- Dismantling of the boiler unit of E-75-40K.

- Basic engineering, technical project, working documentation, Work Performance Project, Method Statements for crane operation, examination, approval, commissioning readiness and assurance.

- Manufacturing and delivery of the boiler E-75-3,9-440 DFT and the boiler accessories.

- Delivery of all equipment (including imported, with customs clearance) and materials.

- Organization and the full range of construction and installation work in all sections of the project:

- Foundations;

- Installation of the boiler carcass;

- Installation of the HYBEX grate;

- Installation of the boiler components (platforms, drums, screens, panels, steam superheaters, air super heaters, primary and secondary economizer); pipelines within the boilers etc);

- Installation of the boiler piping;

- Gas ducts and air ducts;

- Installation of the auxiliary boiler equipment (soot blowing equipment and exhaust fans, conveyors, air heaters etc);

- Installation and setup of Instrumentation and Controls and Automatic Process Control System;

- Installation and setup of the cable systems and illumination light;

- Installation and setup of the insulation and the refractory brickwork;

- Startup and commissioning, operational tuning and putting the boiler unit into operation.

|

|

|

|

|

|

|

|

|

2014 – 2015 Reconstruction of the boiler station No.2 in the city of Yelizovo (Ryabikova Str., 59a) with the construction of an extra gas power block of a carcass type with the block arrangement of the equipment

Client:OAO Kamchatskenergo

Period of execution:2014-2015

Scope of work:

- Preparatory work.

- The equipment and building foundation works.

- Installation of the prefabricated reinforced concrete structures.

- Manufacturing and installation of the construction metal structures.

- Setting up the building envelope and the roofing.

- Installation of the utility networks.

- Supply of equipment and materials.

|

||||

|

|

|||

|

|

|

||

2013 Reconstruction of the turbinal house of the boiler-turbine shop of the Thermal Power Plant 3 with the installation of two turbines R-32-8,8/0,65 station No.1 and R-27-8,8/1,35 station No. 4

Client:OAO Ilim Group Bratsk office

Period of execution:2012 – 2013

Scope of work:

- Development of Work Performance Project, preparatory work

- Manufacturing and supply of support and suspension system of pipelines.

- Manufacturing and supply of piping joints

- Installation of pipelines from boilers to turbines.

- Installation of the turbines’ piping.

- Installation the steam pipelines from the 9,0 MPa soda-regenerating boilers SRK-3000 to the turbines

2012 Construction of boiler SRB-3000 №14 Thermal power plant OAO “ILIM” Group”” Bratsk city.

Client: OAO “ILIM” Group”” Bratsk office.

Period of execution: 2011-2012

Scope of work:

- Development of project for implementation of construction operations, preparatory work.

- Installation of piping and boiler binding fittings and connection to utilities, weight is 100 tons.

- Manufacturing and delivery of the hanger support system of pipelines.

- Installation of piping from SRB-3000 to turbines №1 и №4.

2011 Modernization of boiler Barnaul Boiler Plant -75-39 №8,9 Thermal power plant ОАО «Selengynsky Pulp and Paper Mill»

Client: ОАО «Selengynsky Pulp and Paper Mill»

Period of execution: April – February 2011

Scope of work:

- Replacement of superheater.

- Replacement of feedwater economizer.

- Replacement of air preheater.

- Replacement of desuperheater.

- Replacement of water wall tube furnance.

- Replacement of downcomer and water wall tubes.

- Repair of rotating boiler machinery.

2010 Modernization of boiler Barnaul Boiler Plant -75-39 №6 thermal power plant ОАО «Selengynsky Pulp and Paper Mill»

Client: ОАО «Selengynsky Pulp and Paper Mill»

Period of execution: August – November 2010

Scope of work:

- Development of project for implementation of construction operations, preparatory work.

- Replacement of superheater.

- Replacement of ceiling superheater.

- Replacement of desuperheater.

- Replacement of front curtainwall.

- Replacement of downcomer and water wall tubes.

- Repair of boiler frame.

2010 Reconstruction of the soda recovery boiler unit SRB-1750, №11 Thermal Power Station

Client:OAO “ILIM” Group”” Bratsk office.

The project participants:ОАО «Belenergoremnaladka» (Republic of Belarus, Minsk city)

Period of execution: May 12 to May 21, 2010 (10 days)

The scope of work:

- Development of project for implementation of construction operations, preparatory work.

- Replacement of the superheater.

- Replacement of separation drum.

|

|

|

|

|

2009-2010 Construction of the boiler unit Е-90-3,9-440 ДФТ №15

Client: OAO “ILIM” Group”” Bratsk office.

The project participants:ООО «Energotehnomash», Metso Power OY (Finland), ООО «InterKon» Belgorod city

Period of execution:

Start of design works – October 2007

Foundations – May-August 2008

Temporary lack of funding

Main complex of construction and installation works May 2009 – February 2010

The first kindling – February 2010

The final phase of work – March-September 2010

Getting a permit to operate – September 2010

Scope of work:

- Basic engineering, detail design, working documentation, production design of the crane, production design examination, reconciliations, registration in Federal Environmental, Engineering, Russian Technical Supervisory Authority.

- Manufacturing and delivery of the boiler, the weight is 740 tons.

- Delivery of all equipment (including imported, custom clearance) and materials.

- Organization of the whole complex of construction and installation works for all sections of the project.

- The total tonnage of metal and equipment is 1,300 tons.

|

|

|

|

|

|

|

|

|

|

|

|

2006 Replacement of the water economizer for the SRB-1750 No. 11,12, acting as a General contractor

Client:Thermal power station-3 ОАО « Pulp and Paper Mill » (Bratsk city, Irkutsk Oblast)

Authors of the project:«Kvaerner Power Oy» (Finland), ООО «Energomash-Vostochnaya Sibir» (Irkutsk city)

Period of execution:

Supply of equipment: October 31, 2005 – January 31, 2006

Main works: November 15, 2005 – August 31, 2006

Scope of work:

- Basic engineering.

- Detailed design with the supply of technical and installation documentation.

- Manufacturing and delivery of water economizer, the weight of the water economizer is 516 tons, construction and installation works for preparatory replacement of water economizer.

- Disassembly and assembly roofing, etc., putting the object into operation.

|

|

|

|

|

|

2005 Rebuild of the Heat recovery system for the Board Machine, Pulp Mill 1, Stage 2

Client: PM-1 of the PULP MILL (Bratsk, Irkutsk region)

Engineering company: «Metso Paper» (Finland), Engineering Department of the PULP MILL (Bratsk, Irkutsk region)

Duration: May – November 2005

Scope of work::

Manufacturing and installation of the supports – 45 t, air ducts, fans, heaters and pipelines of Ø 32-325, tonnage – 25 t.

2004-2005 Detail Engineering and construction of a boiler to burn liquid chemical wastes, with a capacity of 35 t of steam per hour, acting as a general contractor

Client: ООО «TOKEM» (Kemerovsky JSC «Chimprom», Kemerovo)

Engineering company: ООО «Energomash-Vostochnaya Sivir» (Irkutsk)

Duration: Octover 2004 – October 2005

Scope of work:

- Detail engineering for the project and preparation of relevant documentation.

- Dismantling, manufacturing and delivery of steel constructions, elements and materials for the boiler.

- Erection of the equipment, installation of a smoke stack 45 m.

- Adjustment and start-up.

2004 Erection of a boiler with a capacity of 3.2 t/h, acting as a general contractor

Client: ВЧД-9 st. Ulan-Ude, branch of the Russian Railways (Ulan-Ude)

Engineering company: JSC «Buryatpromstroyprojekt» (Ulan-Ude)

Duration: 1 March 2004 – 25 May 2004

Scope of work:

Delivery and installation of the ТПГУ -3.2-М, construction of the fuel oil pumps, preparation and connection of the utility networks, installation of a smoke stack 32 m.

2003 Engineering works and installation of a boiler house on a turn-key basis. Capacity 20 t/h, hydrogen burning concept, acting as a General contractor

Client: Boiler House109 JSC «Sayanskchimplast» (Sayansk, Irkutsk region)

Engineering company: JSC «Angarskneftechimproject» (Angarsk, Irkutsk region)

Duration:10 July 2003 – 15 April 2004

Scope of work:

- Preparationn of Specifications together with the Client, Detail Engineering for the project, Expertise of the project, delivery of equipment, pipelines, reducing stations and materials within the scope of the project.

- Installation of two БЭМ-10/1,3-210 V bolers.

- Delivery and installation of burners SG-80 (SAACKE, Germany) and boiler equipment, pipelines, process and power equipment, manufacturing and erection of a smoke stack 42 m, installation of the instruments and process control system.

- Connecting the boiler house to the internal utility networks, commissioning.

|

|

|